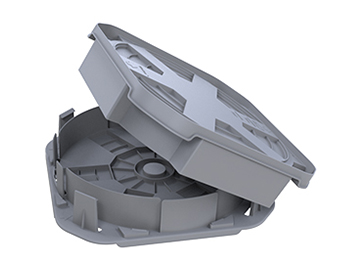

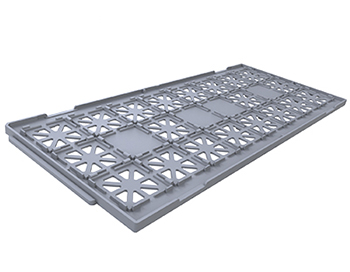

Daewon has a well-trained technical work force to support the core competencies of plastic injection molding technology. Daewon, through years of experience and continuous development of new technologies, offers leading designs and quality products and services.

Daewon has an extended team of experienced design professionals who produce creative solutions to complex technical problems. The team strives to meet the exact requirements of our customers. Daewon designers have a focus on fast time to market in order to deliver value and cost savings to our customers through 2D/3D simulations, DFSS(Design For Six Sigma) and rapid prototyping.

- In house Design Center - Experienced Designers - Design FMEA - 2D/3D Modeling

Tooling

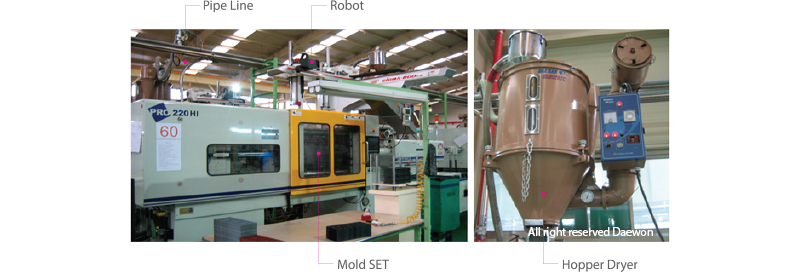

Daewon's tool shop is staffed with the best and most experienced tool makers in the industry.

These tooling experts develop new complex mold tools with the shortest

lead time using the high precision of advanced equipment.

100% In-House Quality Controlled Tooling Shop Advanced CNC, EDM, Grinding, Milling, Polishing, Wire Cut & Laser Welding..

- In-house Tool Shop

- Injection Mold Specialists

- Advanced Equipment

- CAM system

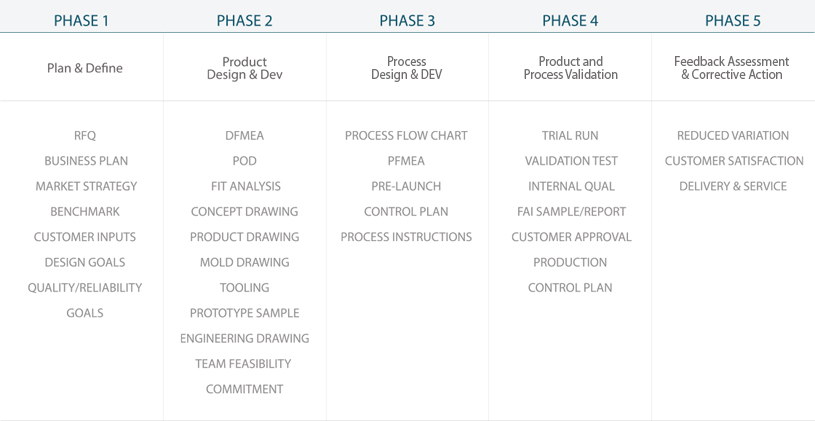

New Product Development Process

Daewon's R&D Center is a leader in the industry, endeavoring to develop new products and new technology according to our new technology roadmap. We can offer our customers highly effective and green products as well as cost innovation.

Cross Functional Team Approach FA Team : Ce / Tooling / Pe / Qa / Sales